Introduction: What is 4D Printing?

When

Skylar Tibbits got up on stage to address his audience at the TED 2013

conference, he presented the project that he has been working on and painted a

picture of his vision for the future. 4D printing: what he believes is the next

step in additive manufacturing (TEDTalks, 2013). At first, it sounds like a

catchy name for a 3D printing technology with an extra feature or two. However,

after watching his whole presentation and upon further reading, it became clear

that this was much more. Although seemingly in the very early stages of

development, 4D printing garners the potential to have countless applications

across industries, and is an innovation that will monumentally disrupt traditional

materials used in industries such as manufacturing, healthcare, and retail.

So,

what is it? Simply put, it is 3D printed material that can change shape upon

interaction with a specific medium. The material’s ability to change shape

comes from a pre-set code that is placed into the printer containing details of

the object’s geometric nature and measurements that detail the object’s behaviour

with an external stimulus. The 4th dimension being time, as the

object’s shape changes over time. Tibbits used water as the medium to spark the

interaction in his presentation, however different material reacts to different

stimuli (@randyrieland,

2014). He placed a printed material in water and, over a period, it changed

from a straight-line shape to the shape of the letters “MIT”. A correct

combination of materials will cause parts of the object to contract and other

parts to relax, folding into a different shape over time. Other stimuli include

temperature, light, and pressure have all proven successful (Stratasys.com,

2013).

Potential and Nature of Innovation

A glance at Gartner’s hype cycle for emerging technologies will show that

4D printing is very much in its early stages of development. Second to last

only beaten by Smart Dust, (sounds more like a sci-fi term than a real technology),

4D printing is estimated to take over 10 years to reach the mainstream (Forni & Meulen, 2016).

Tibbits’ own collaborator Stratasys states that it is still not commercially

available. However, the material’s innovative ability to adapt to its

environment by self-assembly indicates that its agility will prove highly

useful in the future (Stratasys.com, 2013). When placed in the right

circumstances, 4D printed technology has the potential to be the solution for reducing

costs and saving time that is used to assemble and construct traditional

material utilised across industries today. By replacing “legacy” materials with

4D printed ones, companies can be more cost and time-efficient, reducing the

energy and man-hours spent on constructing rigid structures.

As

innovative as 4D printing is, it is not a completely new and radical

innovation. This technology is considered a product performance innovation

since it is printed objects that are SMART because they can adapt to a change

in external stimuli. Product performance innovation is described as updates or

extensions to products that add value through sustainability, customisation,

and simplification. Tibbits describes it as “nothing new” and that the

innovative part is what happens after printing (TEDTalks, 2013).

Who will Develop the Technology?

Currently the institution to introduce the technology is Skylar TIbbits’s

Self-Assembly Lab in partnership with Stratasys, a leading innovative 3D

printing company. It is important to note that there is currently no

standardized hardware design for 4D printing (Khan et. al., 2015).

Stratasys’s Education and R&D departments are collaborating with MIT’s

Self-Assembly Lab (Tibbits) in developing 4D printing. The technology they are

using is the Connex multi-material 3D printing. The SMART materials they use

known as multi-material allow transformation into different shapes and

experiment with the properties to produce insights into geometry and new ways

of transformation. Stratasys and Tibbits are the main developers now, however

there is potential for other companies and institutions to enter the race (Stratasys.com,

2013).

Another technology

being developed is the Rova4D. A successful Kickstarter project, Rova4D is a

different kind of 4D printer. The 4Th dimension they are promoting

is the ability to print using several different colours simultaneously, unlike an

average 3D printer which prints each colour separately. If this technology is

developed further, it could be capable of printing smart materials and become a

4D printer (ROVA,

2016).

United States Institutions have received grants from the U.S. army

research office to develop 4D printed materials. The University of Pittsburgh

is one example where adaptive 4D printed materials are currently being

developed after a research grant of $855,00 (News.Pitt, 2013).

The University of Colorado Boulder has their researchers deep in the

development of composite materials that are adaptive and go a step above 3D

printing (Qi,

2013). These materials can be used in manufacturing, packaging

and biomedical applications. These among other institutions across the United

States have been granted funding primarily for the fields of aerospace, military,

manufacturing, and healthcare.

Competences Needed

The competences and skills needed to develop this technology are built on

existing skills required for 3D printing. Understanding how to use 3D printers

is an important skill as 4D printing differs in the blueprint of design and the

materials used. There will be difficulty when assessing the different kinds of

materials and delving into research of how the materials behave. The team at

Wollongong University in Australia is experimenting with materials to try and

find a solution for the irreversibility and strain of the 4D print. A

limitation of this material is after they have changed shape, the effect is permanent.

The team experimented with ICE gel (ionic covalent entanglement) which

increases the strength of the material and prevents it from cracking if there

is strain (Wassmer,

2015).

The example above highlights one aspect of risk of using this technology

that may require gaining competences in and understanding different solutions

in the event of failure.

Another skill required is the ability to code useful blueprints and

design for the shapes and structures of these materials. This will be essential

for the growth and expansion of this technology so that new innovative methods

for the materials to change shape will arise.

Another

competency is the understanding of the behaviours of different SMART material

and the ability of workers to combine them adequately. 4D printed materials

change shape and conform because of the structure and interaction of materials.

There are several examples of SMART materials including polymeric gal,

self-healing materials, smart metal alloys, and Piezoelectric material. When

pyro-electric material experiences a change in temperature, it emits an electric

signal. This can be applied to opening doors via personnel sensors (Khan

et. al., 2015). Another example is the material used to make the

LG G-flex phone cover, which is a self-healing material that reacts after it

gets scratched. These materials and more all differ in their phases of

development, as some materials will enter their commerciality prior to others. Knowing

how to use these materials is essential to the matter behaving as intended, and

will need investment into R&D and training.

In terms of commercialising the technology, it is advantageous that the

3D printing market exists and is in full swing. Although 4D printers are

inherently different, they have a basis to work from that other innovative

technologies might have not.

Competition

The competition will come both from the 3D printing industry and external

industries that can benefit from the technology. Stratasys and Tibbits are at

the forefront now, but sooner or later other 3D printing companies will begin

to develop their own capabilities of using SMART materials. The issue can come

from patents and IP; however, it is still very open in that regard, with

patents increasing every year. The product’s ability to transform into

different structures may make things complicated, as some patents are issued

for whole product lines (Khan et. al., 2015).

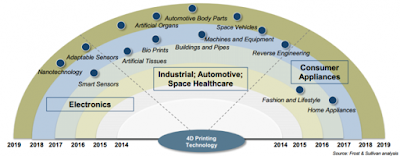

In terms of regional competition,

the chart below highlights the key advances in the different regions of North

America, Europe, and Asia-Pacific.

Source:

Frost, Sullivan 2014

As is the case

with most innovations, North America sees the highest intensity of adoption,

and the most funding injected into the R&D for 4D printing (Khan

et. al., 2015).

In terms of external competition, the

competition will come from innovative companies that have funding and

capabilities to invest in 4D printing research. In the healthcare industry, for

example, hospitals and medical institutions will begin to research and develop

this technology, much like they did with 3D printing before. The United States department

of Defence is an enabler of this competition, providing funding as explained

previously.

Applications of Disruption Across Industries

Before

looking at applications on a macro scale, there have been advances on a

micro-biological scale, specifically in nanotechnology. Although not directly

called 4D printing, scientists have developed physical and micro-biological

materials that can change shapes and directions. One such example that Tibbits

mentions is the use of nano-sized materials comprised of DNA that act as small

computers. When placed in small animals such as bugs, it can allow the organism

to perform small logic operations (Spickernell, 2014). This technology can pave

the groundwork achieving successful implementation in large industries in the

future.

Healthcare

In healthcare, doctors have been working with 4D printed structures that

can be used as implantations in the body. By changing shape over time and

conforming to their surroundings, 4D printed materials are more sustainable

than any other material used. For example, the University of Michigan developed

4D printed structures known as splints in a patient born with bronchomalacia,

weak cartilage in the bronchial tubes. The splints hold open airways and act in

the place of the cartilage, as it reforms into the body. They are said to last

around 2-3 years. This indication means that 4D printing can be successfully

implemented as a solution for medical diseases.

Source: http://www.computerworld.com/article/3071666/3d-printing/how-4d-printing-is-now-saving-lives.html

Above is a picture of the 4D printed

stints implanted in the patients. The main difference between 4D technology and

3D is that of rigidity. The adaptive nature of the 4D printed material gives it

an advantage because it can be sustained in the event of changes in the

environment around it. Of course, there are risks such as lack of compatibility

with the patient’s immune system, or no room for expansion of the material (Mearian,

2016).

Other developments are in very early

phases. Scientists are trying to use 4D printing to create self-folding proteins,

that can later be used for structural purposes. Other applications include

using materials for facial reconstruction, rebuilding cartilage, and holding

tissues in place. These examples show the potential of 4D printing to enact

change in the treatments and processes used in healthcare today. If 4D printed

materials are proven to be objectively superior to the rigid 3D prints, then

they will be entirely disruptive to healthcare treatments in the future.

Construction & Infrastructure

Infrastructure is a core industry that will be disrupted by 4D printed

materials. These materials have the potential to replace many, if not all,

existing materials and technologies used to create infrastructure. For example,

4D printed water pipes can prove to be significantly beneficial, with their

ability to change shape and adapt to changes in the ground such as earthquakes.

Another application is creating piping that acts as a pump, moving water

through the system to the designated location by the expanding and contracting

properties of the material. 4D printed piping material could also mean the ability

to control flow-rates of water, increasing protection and resilience and

decreasing risks of disasters from unattended piping systems. Not only will

this mean reducing investment costs on these devices, but also saving time and

labour costs previously needed to monitor the devices (Innovation, 2015).

Source: https://sites.psu.edu/anirudhnambiar/2013/12/14/extra-blog-4-d-printing-the-future-may-build-itself/

On a larger scale, this technology can affect the process of construction

projects. The idea of self-assembling a large structure such as a desk or a

cabinet could be possible under the right conditions. Imagine the self-assembly

of an entire home out of 4D printed material. This may sound far-fetched, but

if these 4D printed materials are combined correctly and placed in the right

environment, they can transform into any shape required. Houses can be lined

with SMART materials that expand to keep in heat during the winter, and

contract on in the heat (Atlantic Council, 2014).

Retail

In the retail

industry, 4D printed material can be used as a replacement to the material that

clothing is made of. An example is upgrading traditional footwear to “smarter”

shoes. This is done by adding 4D printed material that can change shape and

transform shoes to suit different needs. If the shoe is needed for basketball,

the material will change shape to support the ankles, transforming into

basketball shoes. The same goes for waterproof needs and any other adaptation

to the environment such as hot conditions or high pressure areas (Al-Rodhan,

2014).

Building on the

same idea, these materials can be implemented on clothing for stylistic

purposes. A company called Nervous System designed a 4D printed dress that can

transform into different shapes and expand or shrink to the wearer’s size. This

is advantageous for displaying different fashion styles from the same piece of

clothing, but also for comfort reasons. The key to the design is small hinges

that are printed along with the dress. They allow the piece of clothing to move

and conform to a size accordingly (Innovation, 2015).

Source: https://www.dezeen.com/2014/12/09/moma-acquires-first-4d-printed-dress-nervous-system-kinematics/

These are major disruptions to all three industries highlighted, however

there are many other applications for 4D printing that are being developed

every day. The image below shows the extent of these applications.

One thing is for certain: 4D

printed materials have the potential to change the way we approach everyday

problems and reshape the processes we use to solve them.

Barriers to Adoption

With any potentially disruptive technology comes challenges along the way.

4D printing will face barriers to adoption including regulation barriers, lack

of technical expertise, and resistance to new technology. Given that Tibbits is

the main supplier of this technology now, any new entrant supplying 4D printing

technology will have high barriers to entry and difficulty in competition. These

barriers will slow down the rate of progression of the technology as well as the

time to market.

The first barrier is the lack of experience dealing with the technology

itself. 4D printing is very new and it will take time for the technology to be

accepted in the mainstream. There are a few elements to consider here: the

software involved, the programmable matter itself, and the know-how needed to

combine the materials into the perfect fit. Failure to develop any one of those

three aspects will lead to investors potentially veering away from it due to

high risk. With pre-existing 3D printers and experts in the field, it will be

easier for 4D printing to be accepted in the industry. My recommendation is for

the companies that adopt 4D printing to invest in training. This will not be as

expensive since it is an innovation that builds on existing ideas, easing the

learning process.

For software in specific, existing additive manufacturing devices will

need to have their coding and internal software updated to be compatible with

the programmable matter that is complex, multi-material, and multifunctional. Tibbits

himself has expressed that bringing 4D printing to human scale industries such

as construction will be challenging (Atlantic Council, 2014).

But as stated previously, investment in training software developers to

understand how to create the blueprint for the 4D printed material is the most efficient

way to overcome this barrier.

The second barrier is regulation. There will need to be standardization

of design. This means there is a standard operations protocol agreed upon to

ensure that the systems and materials undergo faultless interaction (Atlantic

Council, 2014). Since standards previously exist for 3D printing,

the issue here is whether these standards are updated and moved over to the 4D

systems, or will new standards be created? Regardless, it will lead to a

slowdown in the time to market of the technology. The second legal aspect is

certifications, which might prove to be tedious like standardization. This

innovation will either need new certifications as per FAA certifications or through

the usual means. The more complicated aspect of legality will arise in the

event of failure or harm done by the technology. Since there are many players

involved, (manufacturer, software developer, materials provider) it will be

difficult to determine who is to blame for this failure. Thus, guidelines will

need to be drawn out ensuring proper conduct.

The last of the barriers is the willingness of companies to take the leap

and implement 4D printing. This is less of a concrete barrier but nevertheless important

to the lifespan and application of 4D printing. How willing are companies in

industries such as infrastructure, retail, and Healthcare, to take the risk and

invest in 4D printing technology? The high risk of a new technology and the

switching costs involved (potentially from 3D material) will mean a lack of

willingness to adopt early on. My recommendation here is to target a niche and

focus on serving a small portion of the market. Over time, the technology will expand

and target other sectors of the industry.

Conclusion

There are very few technologies that have as much potential staring us in

the eyes as 4D printing does. The technology’s key characteristics of adaptive,

complex, shape-changing, conforming multi-material coupled with its variety of

SMART materials capable of reacting to several different stimuli, proves that

it has the potential to disrupt several major industries worldwide. Although

the technology is currently in early phases, the amount of IP is increasing

every year, and the next decade will prove crucial to the development of

innovative processes capable of handling this material (Khan et. al., 2015).

Manufacturing alone will be completely changed, as an increase in efficiency

will see the production of new materials to build infrastructure with, transforming

our capitals into truly “Smart” cities.

References

1. Atlantic Council,. (2014). THE

NEXT WAVE: 4D PRINTING PROGRAMMING THE MATERIAL WORLD. BRENT SCOWCROFT

CENTER ON INTERNATIONAL SECURITY. Retrieved from http://www.atlanticcouncil.org/images/publications/The_Next_Wave_4D_Printing_Programming_the_Material_World.pdf

2. Al-Rodhan, N. (2014). Programmable

Matter: 4D Printing’s Promises and Risks |. Journal.georgetown.edu.

Retrieved 3 March 2017, from http://journal.georgetown.edu/programmable-matter-4d-printings-promises-and-risks/

3. Forni, A. & Meulen, R. (2016). Gartner's 2016

Hype Cycle for Emerging Technologies Identifies Three Key Trends That

Organizations Must Track to Gain Competitive Advantage. Gartner.com.

Retrieved 3 March 2017, from http://www.gartner.com/newsroom/id/3412017

4. Innovation, T. (2015). 4D

printing vs. 3D printing: What’s the difference? - iQ UK. iQ UK.

Retrieved 3 March 2017, from http://iq.intel.co.uk/4d-printing-vs-3d-printing-whats-the-difference

5. Khan, I., Siew, L., Yuan, L., Naing,

M., & Anthony, S. (2015). 4D Printing with Smart Materials. Presentation.

6. Mearian, L. (2016). How 4D

printing is now saving lives. Computerworld. Retrieved 3 March 2017,

from http://www.computerworld.com/article/3071666/3d-printing/how-4d-printing-is-now-saving-lives.html

7. News.Pitt,. (2013). Entering a

New Dimension: 4D Printing | University of Pittsburgh News. News.pitt.edu.

Retrieved 3 March 2017, from http://www.news.pitt.edu/news/entering-new-dimension-4d-printing

8. Qi, J. (2013). CU-Boulder

researchers develop 4D printing technology for composite materials | CU Boulder

Today | University of Colorado Boulder. Colorado.edu. Retrieved 3

March 2017, from http://www.colorado.edu/today/2013/10/22/cu-boulder-researchers-develop-4d-printing-technology-composite-materials

9. @randyrieland, F. (2014). Forget the 3D Printer: 4D

Printing Could Change Everything. Smithsonian. Retrieved 3 March

2017, from http://www.smithsonianmag.com/innovation/Objects-That-Change-Shape-On-Their-Own-180951449/

10. ROVA,. (2016). RoVa4D Full Color

Blender 3D Printer. Kickstarter. Retrieved 3 March 2017, from https://www.kickstarter.com/projects/ordsolutions/rova4d-full-color-blender-3d-printer/description

11. Spickernell, S. (2014). DNA

nanobots deliver drugs in living cockroaches. New Scientist.

Retrieved 3 March 2017, from

https://www.newscientist.com/article/dn25376-dna-nanobots-deliver-drugs-in-living-cockroaches/

12. 4D Printing Technology | Stratasys. (2013). Stratasys.com. Retrieved 3 March

2017, from http://www.stratasys.com/industries/education/research/4d-printing-project

13. The emergence of "4D printing" | Skylar

Tibbits. (2013). LA, California.

14. Wassmer, W. (2015). 4D Printing:

The Smart Materials of The Future. AZoM.com. Retrieved 3 March 2017,

from http://www.azom.com/article.aspx?ArticleID=12387